The selection of Antibody-Drug Conjugates (ADCs) among the 2025 Top Ten Global Engineering Achievements marks a watershed moment in biomedical engineering, representing the culmination of decades of interdisciplinary innovation. These sophisticated therapeutic agents, often described as "biological smart bombs," have transcended their initial promise to become transformative tools in oncology and beyond. The recognition underscores how engineering principles—from precise molecular design to scalable manufacturing—have fundamentally reshaped therapeutic possibilities. What began as a theoretical concept in the late 20th century has evolved into a robust engineering discipline, merging biological insight with chemical precision and industrial rigor.

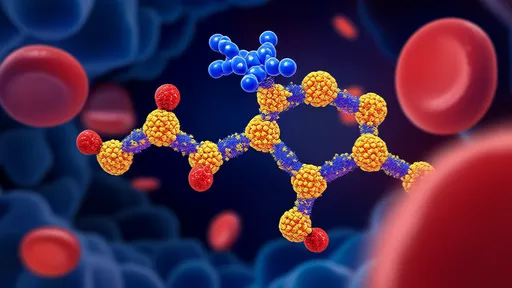

At its core, the ADC paradigm represents a triumph of targeted engineering over conventional therapeutic scattergun approaches. The fundamental architecture—a monoclonal antibody tethered to a potent cytotoxic payload via a specialized chemical linker—demands exquisite precision at every stage. Monoclonal antibodies, themselves products of biological engineering, serve as guidance systems with near-perfect specificity for tumor-associated antigens. Unlike traditional chemotherapy that indiscriminately attacks dividing cells, ADCs employ biological recognition to deliver their deadly cargo exclusively to malignant cells. This targeted approach demonstrates how engineering principles can create solutions that maximize therapeutic impact while minimizing collateral damage.

The engineering challenges in ADC development are monumental, requiring innovations across multiple domains. Linker technology represents perhaps the most critical engineering achievement—these molecular bridges must remain stable during circulation yet release their payload precisely within target cells. Early linker designs faced limitations in stability and controlled cleavage, but next-generation linkers now incorporate sophisticated chemical motifs that respond to specific intracellular conditions. Enzyme-cleavable linkers harness tumor-associated proteases, while acid-labile linkers capitalize on the acidic environment of endosomes and lysosomes. The evolution from simple disulfide bonds to complex, condition-sensitive structures exemplifies how chemical engineering has matured to meet biological complexity.

Manufacturing ADCs at commercial scale presents another layer of engineering innovation. The conjugation process demands extraordinary precision—typically achieving drug-to-antibody ratios within narrow tolerances while maintaining antibody integrity and payload potency. Process engineers have developed sophisticated control systems that monitor conjugation reactions in real-time, adjusting parameters to ensure batch-to-batch consistency. The transition from stochastic conjugation methods to site-specific engineering represents a quantum leap in manufacturing quality. By introducing specific amino acid mutations or incorporating non-natural amino acids, engineers can now direct conjugation to predetermined sites, creating homogeneous ADC populations with optimized pharmacological properties.

The analytical framework supporting ADC development constitutes an engineering discipline in itself. Characterization technologies have evolved to address the profound complexity of these molecules, employing mass spectrometry, capillary electrophoresis, and advanced chromatography to monitor critical quality attributes. Engineering innovations in microfluidics and lab-on-a-chip technologies now enable high-throughput screening of ADC candidates, dramatically accelerating the development timeline. The integration of artificial intelligence and machine learning has further transformed ADC engineering, with predictive algorithms guiding linker selection, payload optimization, and even patient stratification strategies.

Clinical implementation of ADCs has driven engineering innovations in companion diagnostics and treatment monitoring. The development of quantitative assays to measure target antigen expression represents a crucial engineering achievement, enabling precise patient selection. Imaging technologies have evolved to visualize ADC distribution in real-time, providing unprecedented insights into tumor targeting and normal tissue exposure. These diagnostic advances, coupled with engineered approaches to manage and mitigate toxicities, have transformed ADCs from investigational agents into mainstream therapeutics. The engineering mindset—systematic problem-solving, iterative optimization, and holistic system design—permeates every aspect of ADC clinical development.

The expansion of ADC applications beyond oncology highlights the platform's engineering versatility. Infectious disease targets, particularly in antimicrobial-resistant pathogens, represent a frontier where ADC engineering shows particular promise. By targeting bacterial surface proteins with antibody-guided antibiotics, engineers are creating solutions to one of healthcare's most pressing challenges. Similarly, autoimmune and inflammatory conditions are being addressed through targeted delivery of immunomodulatory agents. This therapeutic expansion demonstrates how a well-engineered platform can transcend its original application domain, creating solutions across the medical spectrum.

Global collaboration has been essential to ADC engineering progress, with contributions spanning academic institutions, pharmaceutical companies, and regulatory agencies. The establishment of standardized characterization methods and quality control frameworks represents a significant engineering achievement in global harmonization. International consortia have developed shared databases of ADC properties and performance characteristics, creating collective knowledge that accelerates future innovation. This collaborative engineering approach has compressed development timelines while enhancing safety profiles, demonstrating how shared engineering standards benefit the entire therapeutic ecosystem.

The economic and accessibility dimensions of ADC engineering present ongoing challenges and opportunities. Manufacturing efficiency improvements have steadily reduced production costs, though significant barriers remain for global access. Engineering innovations in single-use bioreactor systems, continuous manufacturing processes, and purification technologies continue to drive down costs while increasing capacity. The emergence of biosimilar ADCs represents the next frontier in engineering-driven accessibility, requiring novel analytical approaches to demonstrate equivalence for these complex molecules. These efforts highlight how engineering considerations extend beyond technical performance to encompass broader societal impact.

Looking forward, ADC engineering continues to evolve toward greater sophistication and capability. Next-generation platforms incorporating conditional activation, dual targeting, and combination payloads are already advancing through development pipelines. Engineering approaches that modulate ADC properties in response to physiological conditions—so-called "smart ADCs"—represent the cutting edge of therapeutic design. The integration of ADCs with other modalities, particularly immunotherapy, creates synergistic treatment paradigms that leverage the unique strengths of each approach. This continuous innovation cycle ensures that ADC engineering will remain at the forefront of biomedical advancement for the foreseeable future.

The recognition of Antibody-Drug Conjugates as a top global engineering achievement ultimately celebrates more than a specific therapeutic class—it validates an engineering mindset applied to biological challenges. From molecular design to global manufacturing, ADC development exemplifies how systematic engineering principles can transform scientific insight into life-saving medicines. As the field continues to advance, the lessons learned from ADC engineering will undoubtedly influence broader therapeutic innovation, establishing new standards for precision, efficacy, and patient-centered design in medicine.

By /Oct 21, 2025

By /Oct 21, 2025

By /Oct 21, 2025

By /Oct 21, 2025

By /Oct 21, 2025

By /Oct 21, 2025

By /Oct 21, 2025

By William Miller/Oct 20, 2025

By /Oct 20, 2025

By /Oct 21, 2025

By /Oct 20, 2025

By /Oct 21, 2025

By /Oct 20, 2025

By /Oct 20, 2025

By /Oct 21, 2025

By Joshua Howard/Oct 20, 2025

By /Oct 20, 2025

By /Oct 20, 2025

By /Oct 20, 2025

By /Oct 21, 2025