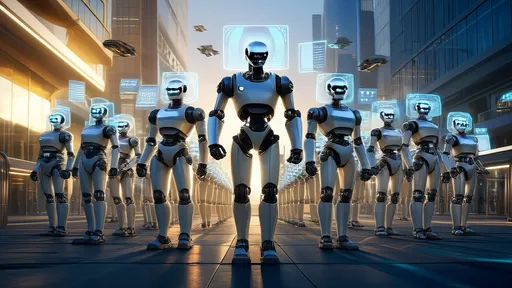

In the quiet hum of laboratories and the bustling floors of manufacturing plants across the globe, a new industrial revolution is taking shape—one defined not by steam or silicon, but by the precise, deliberate movements of humanoid robots. After decades of promise and speculation, the global humanoid robot industry has decisively shifted from a phase of research and niche application into a period of explosive, accelerated development. The convergence of breakthroughs in artificial intelligence, material science, and actuator technology has created a perfect storm, propelling these machines from the pages of science fiction into the tangible reality of our factories, warehouses, and, increasingly, our daily lives.

The journey of humanoid robotics has been a long and arduous one. For years, the field was dominated by academic projects and high-profile demonstrations that, while technologically impressive, struggled with practical limitations. Robots were often unstable, energy-inefficient, and prohibitively expensive. They operated in controlled environments, performing scripted tasks. However, the foundational work of these past years has not been in vain. It has provided the essential data, the hard-won insights into bipedal locomotion, and the understanding of human-robot interaction that are now bearing fruit. The industry is no longer just proving that a machine can walk on two legs; it is now focused on what that machine can do, and how efficiently it can do it.

A critical catalyst for this acceleration has been the unprecedented advancements in Artificial Intelligence, particularly in the realms of large language models and embodied AI. Modern humanoid robots are no longer mere puppets executing pre-programmed code. They are increasingly endowed with the ability to perceive, reason, and act in complex, unstructured environments. An AI brain allows a robot to understand natural language commands like "please tidy up this workshop" and break it down into a sequence of actionable steps—navigating around obstacles, identifying tools, and manipulating objects with a degree of adaptability that was previously unimaginable. This shift from deterministic programming to cognitive, learning-based systems is what truly unlocks the potential for humanoid robots to become versatile partners rather than specialized tools.

Simultaneously, the physical embodiment of these robots has undergone a dramatic transformation. The development of high-torque, low-weight actuators has been a game-changer, enabling more powerful and graceful movements. Innovations in materials, including advanced composites and lightweight alloys, have reduced overall weight without sacrificing structural integrity, leading to improved energy efficiency and safety. Furthermore, the cost of core components, from sensors to batteries, has been on a steady downward trajectory, driven by economies of scale from adjacent industries like electric vehicles and consumer electronics. This has made the prospect of mass-producing capable humanoid robots a financially viable endeavor for a growing number of companies.

The commercial landscape is reflecting this newfound momentum. A dynamic ecosystem is emerging, comprising established industrial automation giants, ambitious startups, and even major technology and automotive firms diversifying their portfolios. This is not a quiet race; it is a loud, public, and highly competitive dash to market. Companies are no longer secretive about their prototypes. They are showcasing them in live demonstrations, releasing videos of robots performing complex tasks in real-world settings, and announcing ambitious timelines for pilot deployments and initial production runs. The level of investment, both from venture capital and corporate R&D budgets, has skyrocketed, signaling a strong market belief in the sector's near-term viability.

The initial application frontier for humanoid robots is clearly in industrial and logistics settings. These environments present a compelling use case: they are often structured yet repetitive and physically demanding for human workers. The humanoid form factor is particularly advantageous here because it is designed to operate in spaces built for humans. A bipedal robot can theoretically navigate a factory floor, climb stairs, and use tools and machinery designed for human operators without requiring a massive and costly retrofit of the existing infrastructure. Early pilots are focusing on tasks such as palletizing, quality inspection, and parts handling—tedious and strenuous jobs that contribute to high employee turnover. By deploying robots for these "3D" (dirty, dangerous, and dull) tasks, companies aim to boost productivity, enhance workplace safety, and free up their human workforce for more complex, value-added roles.

Looking beyond the factory walls, the potential applications begin to expand into more socially complex domains. The healthcare and elderly care sectors, facing severe labor shortages in many countries, view humanoid robots as a potential partial solution. In these settings, robots could assist with patient mobility, monitor vital signs, provide reminders for medication, and offer companionship. The hospitality industry is experimenting with robotic concierges and porters. While these applications are further from widespread commercialization, they represent the long-term vision for the technology—to create machines that can seamlessly integrate into human-centric environments and augment our capabilities.

However, the road to a robot-populated future is not without its significant challenges. Technical hurdles remain, particularly in the domain of reliability and safety. Ensuring that a 150-pound machine can operate safely alongside humans in dynamic, unpredictable scenarios is a monumental engineering challenge. Battery life continues to be a constraint, limiting operational uptime. Furthermore, the "general" in general-purpose humanoid robot is still a distant goal. Most current systems excel at a narrow set of tasks but lack the generalized dexterity and common-sense reasoning of a human child. Bridging this gap will require continued fundamental research in AI and robotics.

The societal and ethical implications are equally profound and demand proactive discussion. The potential for widespread job displacement in certain sectors is a legitimate concern that must be addressed through reskilling and education initiatives. The development of clear safety standards and regulatory frameworks is urgently needed to govern the deployment and operation of these powerful machines. Questions of liability in case of accidents, data privacy for robots that perceive their surroundings, and the long-term psychological impact of human-robot interaction are all critical areas that require input from ethicists, policymakers, and the public at large.

Despite these challenges, the trajectory is unmistakable. The global humanoid robot industry has moved past its infancy and is now in a vigorous, adolescent growth spurt. The convergence of enabling technologies, intense commercial competition, and clear market demand has created a powerful feedback loop of innovation. We are witnessing the transition from prototype to product. The coming years will not be about if humanoid robots will become a common sight, but rather where they will first become ubiquitous and how they will transform the nature of work and society. The fast lane is now open, and the industry is accelerating into a future that is being built, quite literally, one step at a time.

By /Oct 21, 2025

By /Oct 21, 2025

By /Oct 21, 2025

By /Oct 21, 2025

By /Oct 21, 2025

By /Oct 21, 2025

By /Oct 21, 2025

By William Miller/Oct 20, 2025

By /Oct 20, 2025

By /Oct 21, 2025

By /Oct 20, 2025

By /Oct 21, 2025

By /Oct 20, 2025

By /Oct 20, 2025

By /Oct 21, 2025

By Joshua Howard/Oct 20, 2025

By /Oct 20, 2025

By /Oct 20, 2025

By /Oct 20, 2025

By /Oct 21, 2025